- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

HSNQ18F

HSN

84798999

Simple Structure, Easy operation

Copper Recycling

| Availability: | |

|---|---|

| Quantity: | |

Brief Introduction

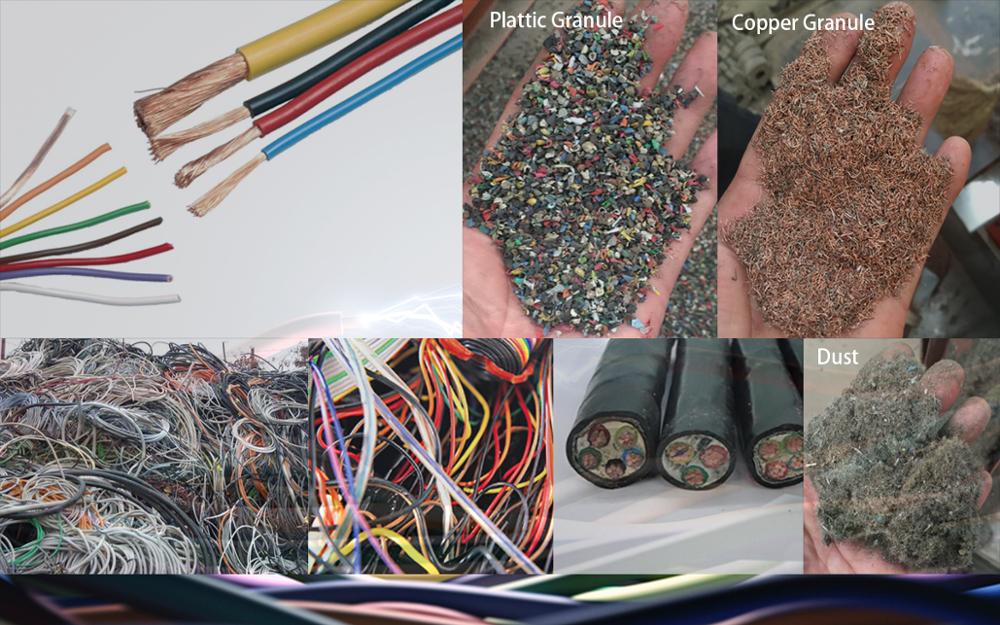

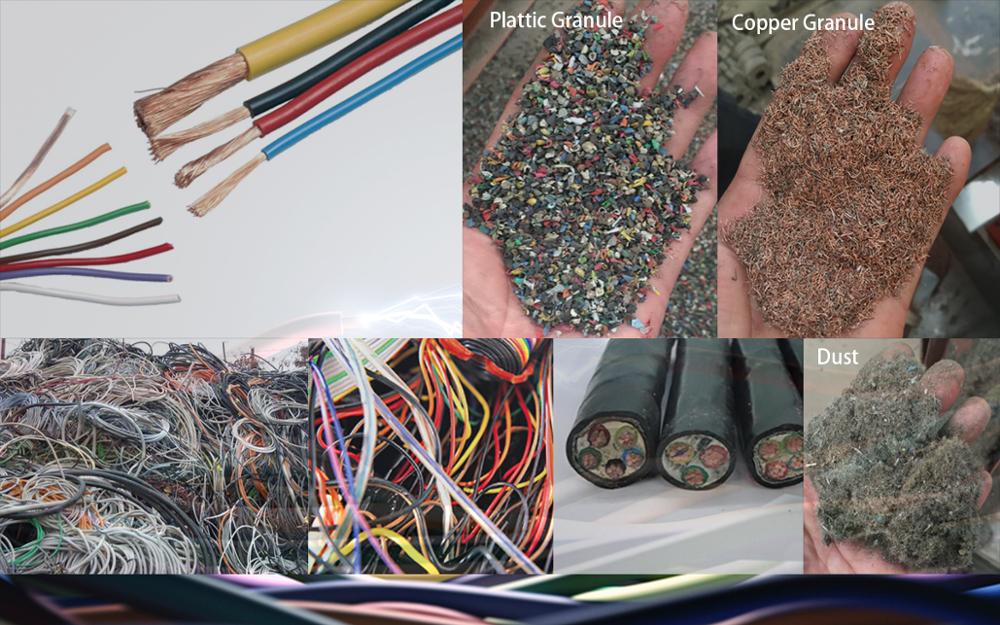

Copper Cable stripping machine is for peeling off cable the outsourced plastic fore skin and metal core wire, because the cable diameter has different sizes and wire material and composition are not same, different cable should be used different suitable models. In the copper waste recycling industry, this machine makes operating system, save time and effort to complete more efficiently in the recycling of waste wire and cable.

We have different capacity machine for you choose. And we also offer customized service.

HSNQ18F Cable Stripping Machine

Simple structure (single roller twin blades), Easy to use, Practical and Affordable.

Technical Specifications

Model | Power | Voltage | Cable Range | Blades | Holes | Output | Size | Weight |

HSNQ18F | 1.5kw | 220V/380V | 1-30mm | 9 | 2+9 | 30meter/minute | 56x55x84cm | 70kg |

Instructions for use

1. Before working, please check whether the machine operating is normal, feed according to the size of the cable diameter, in turn into the corresponding feed hole.

2. In order to extend durability of the blade, when feeding should be cut off connector of rubber cable, so as not to break the blade gap.

3. If the output cable occurrence of too deep and broken wire problem, pay attention to the following situation:

a) should adjust the feed gear, that is the two sides of the spring pressure.

b) when feeding, please check whether misplace the cable position of the feeding hole.

c) if the blade is new changed, whether the edge is too sharp application grinding stone slightly trim, moderate so far.

4. If output cable, the outer skin has been peeled off, but copper wire can’t be exposed. There are mainly the following:

a) spring pressure is too loose, the pressure should be tightened;

b) the upper shaft rolling too deep, please use grinding stone to polish the upper shaft, but avoid to be over-polished, too much grinding easy to cause oily cable lines difficult to drive;

c) the wire diameter is small, or the upper and lower shaft gap is more, appropriate adjustment of the two-axis gap;

d) the processed cable has been hot, copper wire will not be easy to expose to the skin.

5. If after feeding, the crushing gear can not transmission the cable, the material stays in the middle, there are several situations:

a) check each belt if looseness;

b) check whether the spring pressure on both sides of each gear is too tight, there is no force, should relax the pressure;

c) cable oily too much, so that the two axes slip, should always clean the two axes.

Brief Introduction

Copper Cable stripping machine is for peeling off cable the outsourced plastic fore skin and metal core wire, because the cable diameter has different sizes and wire material and composition are not same, different cable should be used different suitable models. In the copper waste recycling industry, this machine makes operating system, save time and effort to complete more efficiently in the recycling of waste wire and cable.

We have different capacity machine for you choose. And we also offer customized service.

HSNQ18F Cable Stripping Machine

Simple structure (single roller twin blades), Easy to use, Practical and Affordable.

Technical Specifications

Model | Power | Voltage | Cable Range | Blades | Holes | Output | Size | Weight |

HSNQ18F | 1.5kw | 220V/380V | 1-30mm | 9 | 2+9 | 30meter/minute | 56x55x84cm | 70kg |

Instructions for use

1. Before working, please check whether the machine operating is normal, feed according to the size of the cable diameter, in turn into the corresponding feed hole.

2. In order to extend durability of the blade, when feeding should be cut off connector of rubber cable, so as not to break the blade gap.

3. If the output cable occurrence of too deep and broken wire problem, pay attention to the following situation:

a) should adjust the feed gear, that is the two sides of the spring pressure.

b) when feeding, please check whether misplace the cable position of the feeding hole.

c) if the blade is new changed, whether the edge is too sharp application grinding stone slightly trim, moderate so far.

4. If output cable, the outer skin has been peeled off, but copper wire can’t be exposed. There are mainly the following:

a) spring pressure is too loose, the pressure should be tightened;

b) the upper shaft rolling too deep, please use grinding stone to polish the upper shaft, but avoid to be over-polished, too much grinding easy to cause oily cable lines difficult to drive;

c) the wire diameter is small, or the upper and lower shaft gap is more, appropriate adjustment of the two-axis gap;

d) the processed cable has been hot, copper wire will not be easy to expose to the skin.

5. If after feeding, the crushing gear can not transmission the cable, the material stays in the middle, there are several situations:

a) check each belt if looseness;

b) check whether the spring pressure on both sides of each gear is too tight, there is no force, should relax the pressure;

c) cable oily too much, so that the two axes slip, should always clean the two axes.